Volvo Makes Every Mile(stone) Count

Big news recently came out of Sweden, home of Volvo Cars, that will have a direct impact on South Carolina’s workforce and economy: the reveal of the Volvo EX90, a true seven-seater, all-electric SUV that represents the company’s high standards in safety and sustainability. “The Volvo EX90 is a statement for where we are and where we are going,” said Jim Rowan, Volvo Cars’ chief executive.

What, exactly, does the SUV’s cutting-edge technology in core computing, connectivity and electrification look like? Single-charge, emission-free, 300-mile range capability. State-of-the-art cameras, radar and lidar that ensure passenger safety. Infotainment systems with high-quality graphics, highly intuitive navigation and immersive sound.

And while the Volvo EX90 may be the culmination of years of hard work and innovation, it is also “the start of something new for Volvo Cars in many ways,” continued Rowan. With plans to reveal one new fully electric car each year, the company aims to sell only fully electric cars by 2030 and be climate-neutral by 2040.

Getting Production-Ready

“These cars will be proudly made right here in South Carolina with local talent, and of course, a little Scandinavian design.”

— David Stenström, Vice President of Manufacturing, Americas, and Plant Manager at Volvo Cars Charleston, in SCBiz’s May/June 2022 Industry Perspective

Volvo Cars’ electrification blueprint is one of the most ambitious in the automotive industry, and its Ridgeville, SC, plant will build all Americas-bound Volvo EX90 models. “These cars will be proudly made right here in South Carolina with local talent, and of course, a little Scandinavian design,” said David Stenström, Vice President of Manufacturing, Americas, and Plant Manager at Volvo Cars Charleston, in SCBiz’s May/June 2022 Industry Perspective.

“Our major focus now is on attracting, recruiting and developing our team as we prepare for the future. Our partnership with readySC will continue to feed our employment pipeline as we plan a second shift to keep up with production demands,” Stenström continued.

Growing Community Engagement

Volvo Cars’ partnership with readySC dates to 2015, when the company first broke ground at its Berkeley County location. By June of 2018, it was fully operational, and today the SC facility manufactures the Volvo S60 luxury compact sedan and – soon – the Volvo EX90 and the Polestar 3.

Looking back, readySC Senior Area Director Terrance Rivers recalls that “community engagement was always a priority for Volvo. The company wanted to feel like a neighbor.” Fast forward to today, and not only has Volvo provided gainful employment for South Carolinians – particularly residents of nearby Berkeley, Charleston and Dorchester Counties – but it has also built strong, sustainable, mutually beneficial relationships with leaders across the Lowcountry. “We do this by serving on community advisory boards, attending STEM and career events at our schools, and giving back to the community through our grant fund,” said Dan Holloway, manager of Plant Academy at Volvo Cars Charleston.

Not only that, but Camp Hall, the commerce park where Volvo Cars is located, focuses on creating a balance between man, nature and machine. Designed with growth in mind and dedicated to the supplier network, the park supports advanced industries of today and tomorrow, while also meeting the everyday needs of workers. Its network of restaurants, healthcare services, outdoor trails, housing and other amenities ensures that Volvo Cars employees thrive in their environment both inside and outside of the plant.

Developing a Top-Talent Workforce

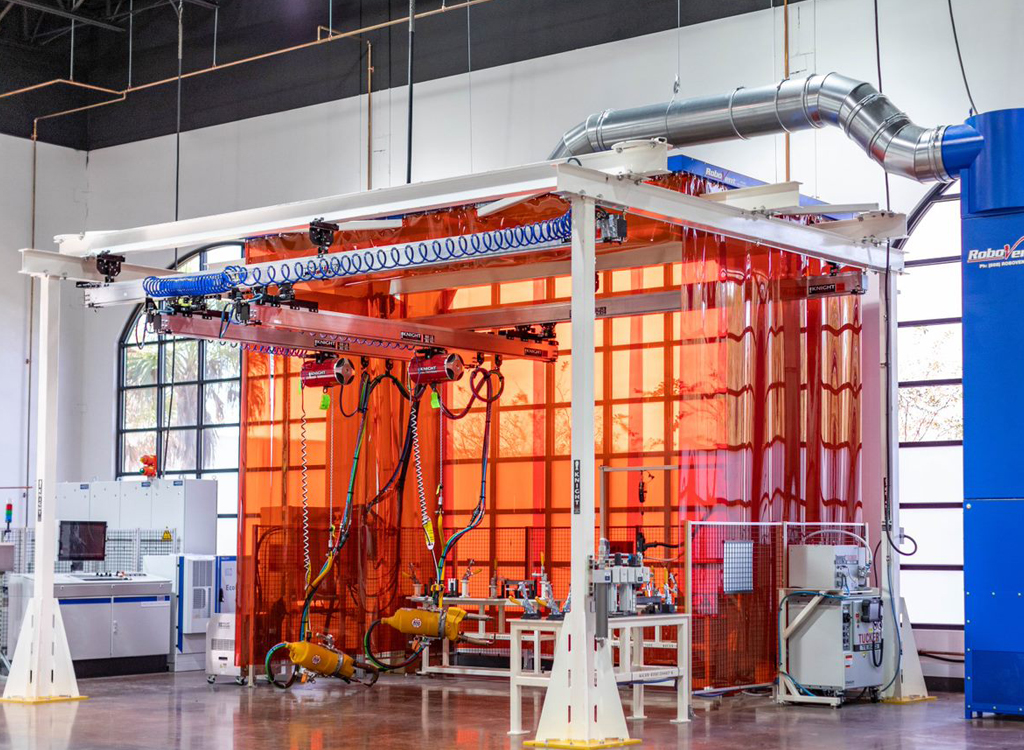

Just as community engagement has expanded over the years, so too has readySC’s training for Volvo Cars. Initial process improvement training took place in Sumter, but by the time readySC installed its Simulated Work Environment (SWE) a few months later, instructors were able to operate the SWE as trainers, assist with maintenance and optimize collaboration and efficiency among employees.

Ask Holloway about his ideal workforce, and he’ll tell you that employees need to have “a good work ethic, a willingness to learn and a positive outlook.” Equally important are problem-solving skills and hand-eye coordination – both of which readySC has been instrumental in refining.

For instance, in response to one of Volvo Cars’ training needs, the readySC team created a training aid that simulated wire harness assembly. As this task is difficult and can lead to serious rework issues if things are not connected properly, readySC designed the training aid with spatial awareness and ergonomics at top of mind.

“Thanks to our great partnership and readySC’s support, we have improved both our pre-hire and post-hire processes.”

— Dan Holloway, manager of Plant Academy at Volvo Cars Charleston

readySC has also assisted with conditioning, as new employees are not always familiar with the job’s physicality or urgency. “Thanks to our great partnership and readySC’s support, we have improved both our pre-hire and post-hire processes,” Holloway said. “We are also in the final stages of putting together our new Industrial Conditioning Environment.” From managing fatigue to working within designated timeframes, readySC and Volvo Cars work together “to ensure that future team members and new hires are prepared to work in a production environment.”

Overcoming Obstacles... Together

A project the size of Volvo Cars is not without its challenges, but strategic partnerships make a difference. When Volvo Cars first came to the Lowcountry, over 50,000 people expressed interest in employment. (You read that right: 50,000!) But readySC and the SC Technical College System were instrumental in helping the company manage such a large number of candidates. “They have also served as an extension of Volvo Cars by attending recruitment events on our behalf, ensuring we reach all of our target markets,” Holloway stated.

On readySC’s end, automation training has posed some difficulties. Employing competent instructors with both textbook knowledge and industry experience in the highly competitive field is no small task! readySC’s initial solution was to outsource the training, but after carefully reviewing vendor capabilities, readySC was able to identify a single vendor, Premier Automation, that currently provides repair, programming and other training to Volvo Cars maintenance technicians.

Ready for the EV Future

As Volvo Cars zooms ahead in the electric vehicle market, other challenges are inevitable. Because the technology is still new and evolving, many questions remain unanswered. “How will the workforce change right now?” Rivers wonders. “How will training aids need to change? What are the safety concerns? What modifications need to be made to the training center – HVAC? Electrical? Firewalls?”

And yet, the questions don’t fluster Rivers. “We’ve had such a collaborative dynamic with Volvo Cars throughout this project. We can easily carry that forward with the training that will be required by the electrification of these vehicles.”

Holloway agrees. “There have been times when we did not have the resources to support a need internally and readySC was available to jump in and help. I know what you’re thinking, but it’s true. It’s right there in the name; readySC is ready!”